Tecnologia Mars

Mais de 10 anos de sucesso inovador em tecnologia

A inovadora Série Mars evoluiu para se tornar uma força motriz essencial para o nosso sucesso, estabelecendo novos padrões em precisão repetitiva, exatidão e economia de energia com seu sistema de acionamento servo-hidráulico. Desde a introdução da Tecnologia Mars em 2006, mais de 230.000 unidades da Série Mars foram vendidas, e os acionamentos servo-hidráulicos tornaram-se indispensáveis para a indústria.

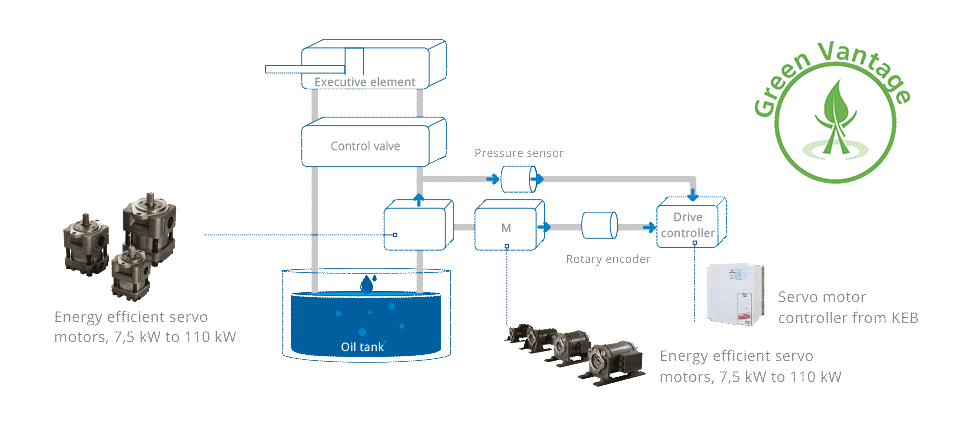

O sistema patenteado de acionamento por servomotor/bomba de engrenagens foi projetado como um sistema integrado e não como uma simples combinação de componentes padrão de mercado, como fazem nossos concorrentes. Isso representa uma vantagem significativa para obter alta precisão repetitiva e baixo consumo de energia em diversas aplicações de moldagem e materiais de processamento.

Tecnologia Patenteada

Sistema de acionamento de economia de energia

Projeto patenteado de servomotor para bomba de engrenagens. A conexão direta entre o servomotor e a bomba de engrenagens proporciona excelente torque de acionamento, garantindo máxima aceleração e desaceleração para todas as funções da máquina. O sistema de acionamento patenteado oferece uma vantagem real em termos de alta estabilidade e condições repetitivas de moldagem.

Os servomotores variam de 7,5 kW a 110 kW e são especialmente projetados para atender às altas exigências do processo de injeção de plástico.

O controlador de servomotor europeu da KEB é combinado ao motor de acionamento para obter máxima eficiência e precisão repetitiva.

Bomba de engrenagens de alta eficiência para operação estável e baixo consumo de energia.

EXEMPLO DE DESEMPENHO

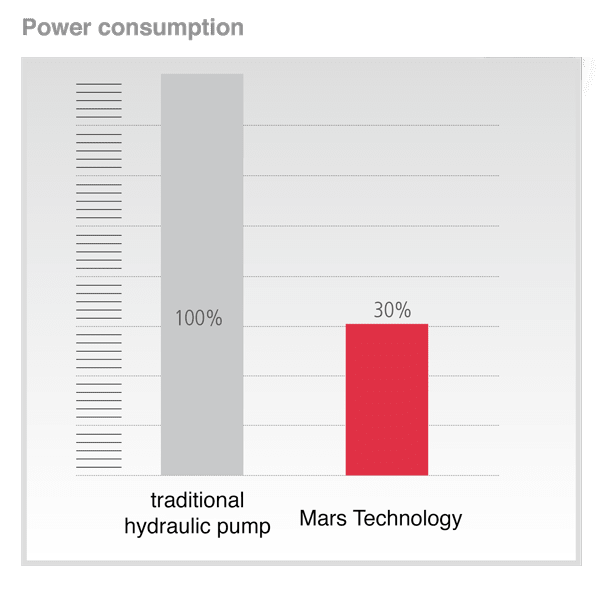

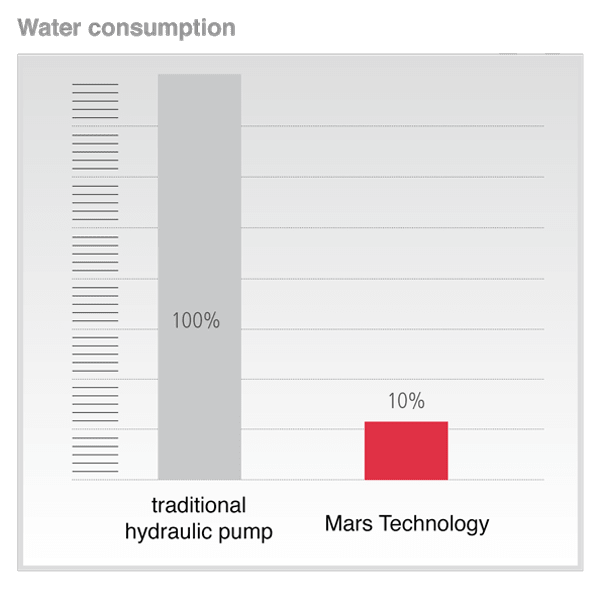

EFICIÊNCIA ENERGÉTICA NO MARS

Impulsionador de Crescimento

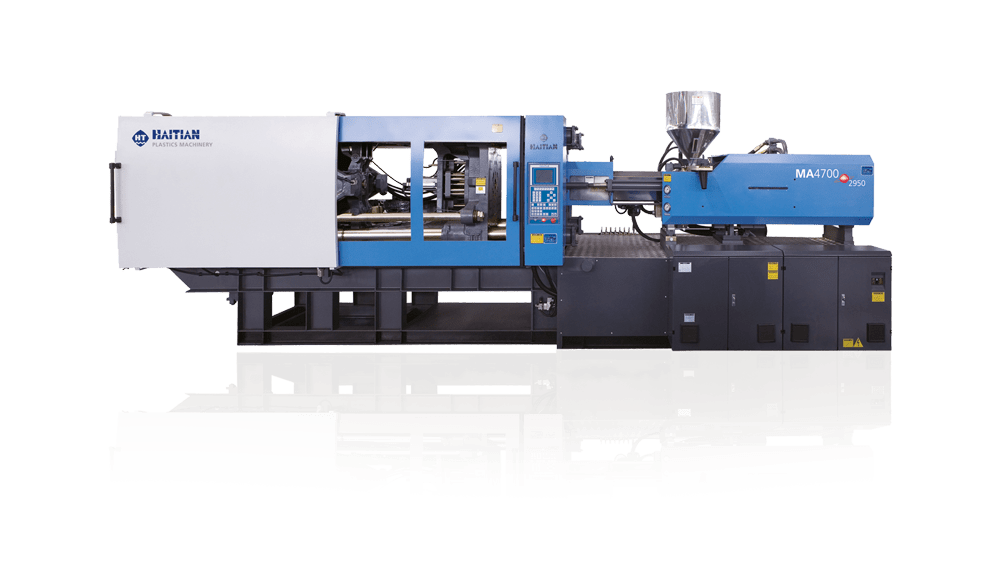

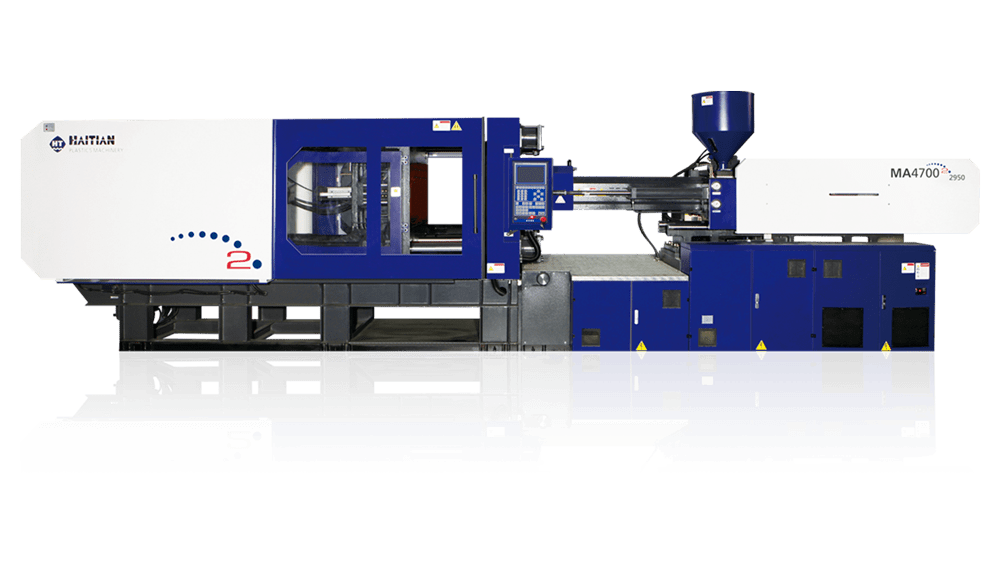

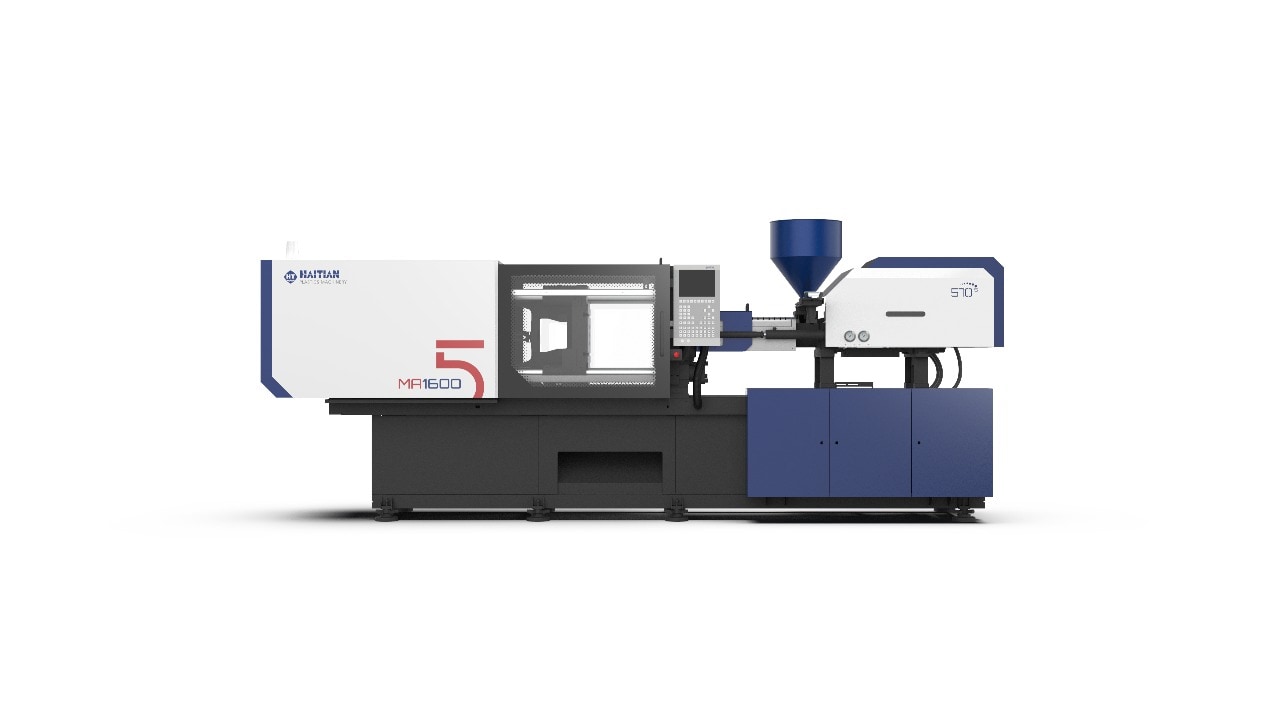

A SÉRIE HAITIAN MARS

2006

A GERAÇÃO 1 DA MARS ENTROU EM PRODUÇÃO EM SÉRIE.

2012

A GERAÇÃO 2 DA MARS ENTROU EM PRODUÇÃO EM SÉRIE.

Até o momento

A TECNOLOGIA MARS AGORA É UM EQUIPAMENTO PADRÃO EM VÁRIAS MÁQUINAS HAITIAN.

DESCUBRA A MARS

UMA HISTÓRIA DE SUCESSO

A Mars está no mercado há mais de 10 anos e continua sendo líder em tecnologia de moldagem por injeção hidráulica – a máquina de injeção mais vendida no mundo.