MARS TECHNOLOGY

Energy saving drive system

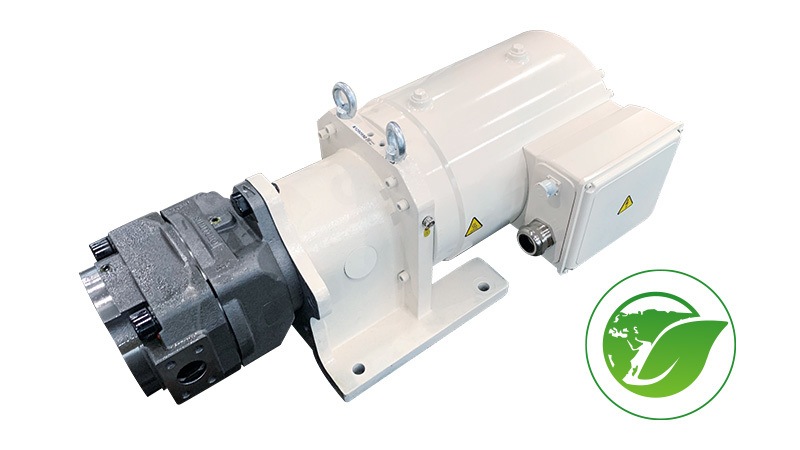

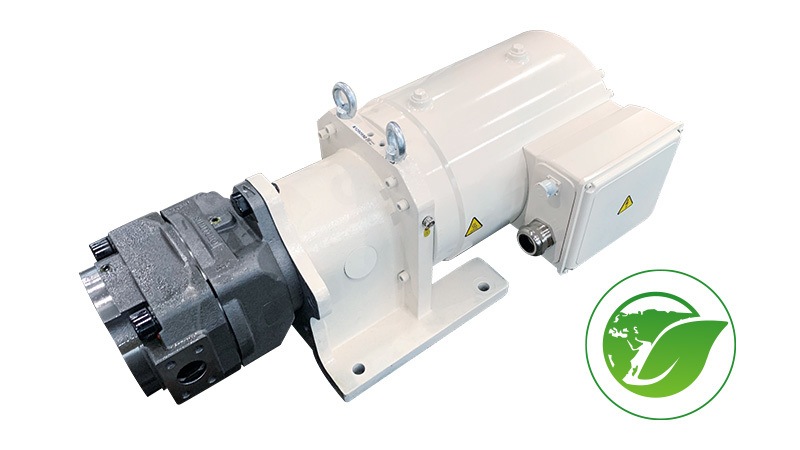

Continuous improvements and the consistent further development of standard components such as the successful „Mars Technology“ result in higher performance but also higher overall resource savings. Since its introduction of the Mars Technology in 2006, more than 250,000 Haitian machines with this innovative technology have been sold and servo-hydraulic drives are now indispensable to the industry. The patented servo motor/gear pump drive system is designed as a system and is not the combination of standard market components as used by our competitors. This translates into a significant advantage for repeatable high precision and low energy consumption for different molding applications and processing materials.

PATENTED TECHNOLOGY

Servomotor + Gear Pump

The direct drive connection between the servo-motor and the gear pump provides excellent drive torque giving maximum acceleration and deceleration speeds for all machine functions. The patented drive system is a true advantage for high stability and repeatable molding conditions. Servo motors ranging from 7.5 kW to 110 kW comes with increased system pressure which means faster servo frequency, improved from 200mm/s to 205mm/s.

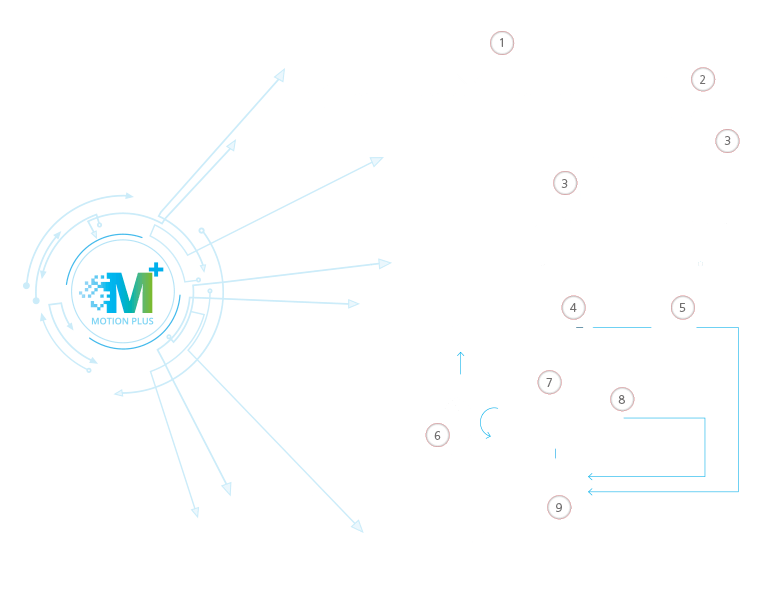

NEW GENERATION

Intelligent Motion Control

The new high-drive servo system is combined with a fully digital Bus control system for high dynamics and high responsiveness. Thanks to intelligent algorithms, we have optimized the injection process so that we can replace proportional valves with normal standard valves – closed-loop, without loss of speed and pressure. Dynamic algorithms take into account mold weight, oil temperature, lubrication and other conditions for optimum mold movement.

1_Injection cylinder

2_Hydraulic motor

3_On-off valve

4_Pressur sensor

5_J6 Box

6_Gear pump

7_Servo motor

8_Rotary encoder

9_Drive controller

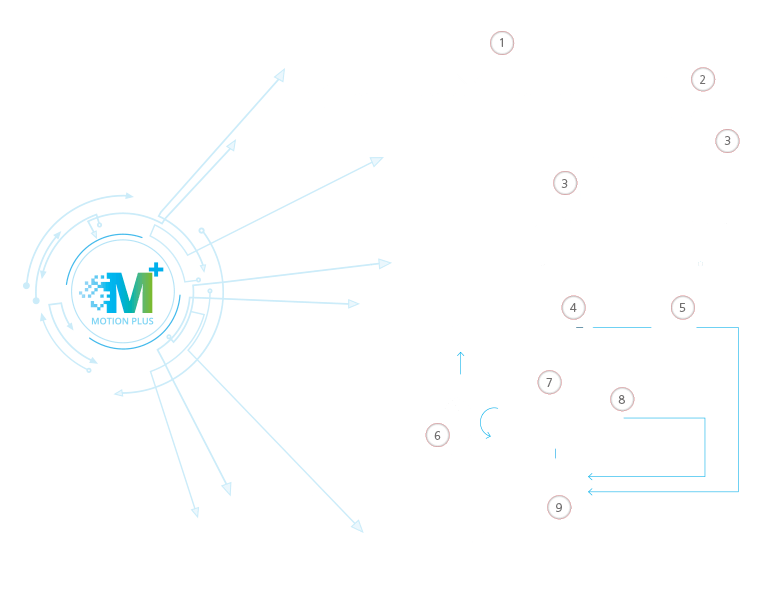

The new high-drive servo system is combined with a fully digital Bus control system for high dynamics and high responsiveness. Thanks to intelligent algorithms, we have optimized the injection process so that we can replace proportional valves with normal standard valves – closed-loop, without loss of speed and pressure. Dynamic algorithms take into account mold weight, oil temperature, lubrication and other conditions for optimum mold movement.

1_Injection cylinder

2_Hydraulic motor

3_On-off valve

4_Pressur sensor

5_J6 Box

6_Gear pump

7_Servo motor

8_Rotary encoder

9_Drive controller

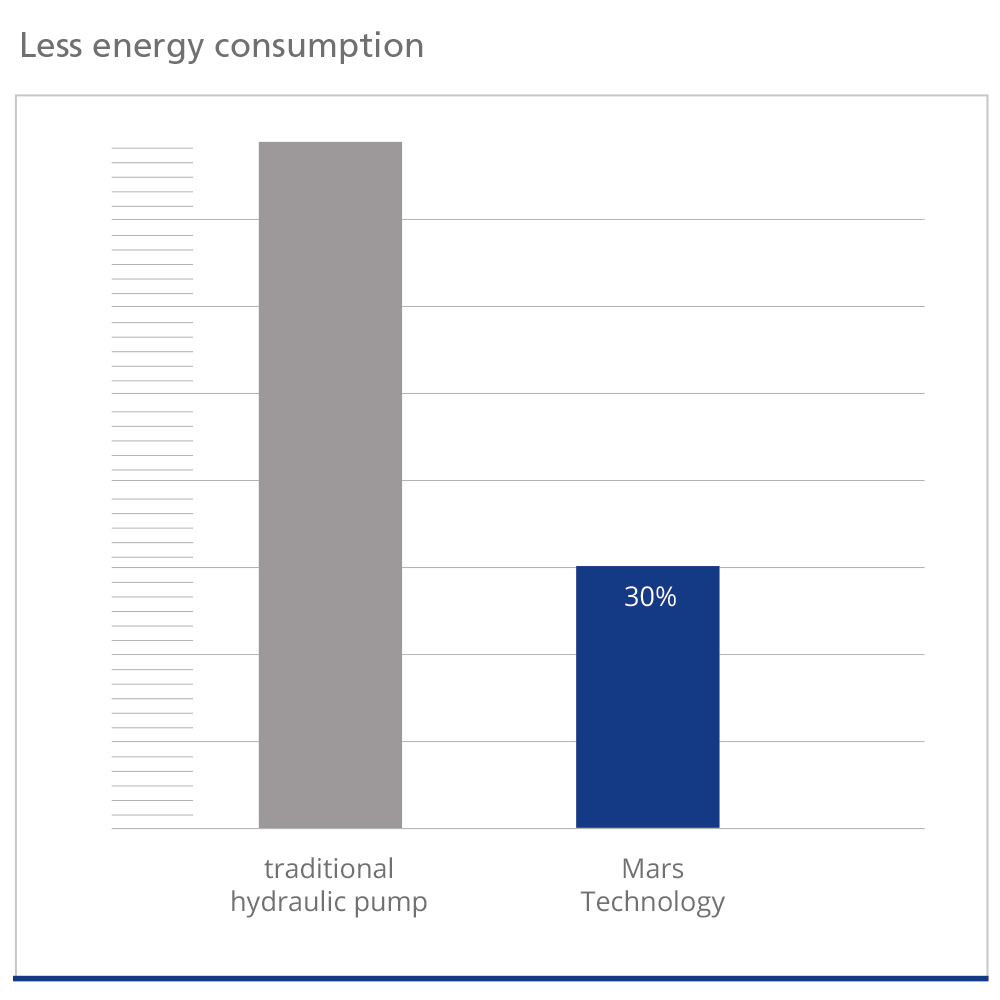

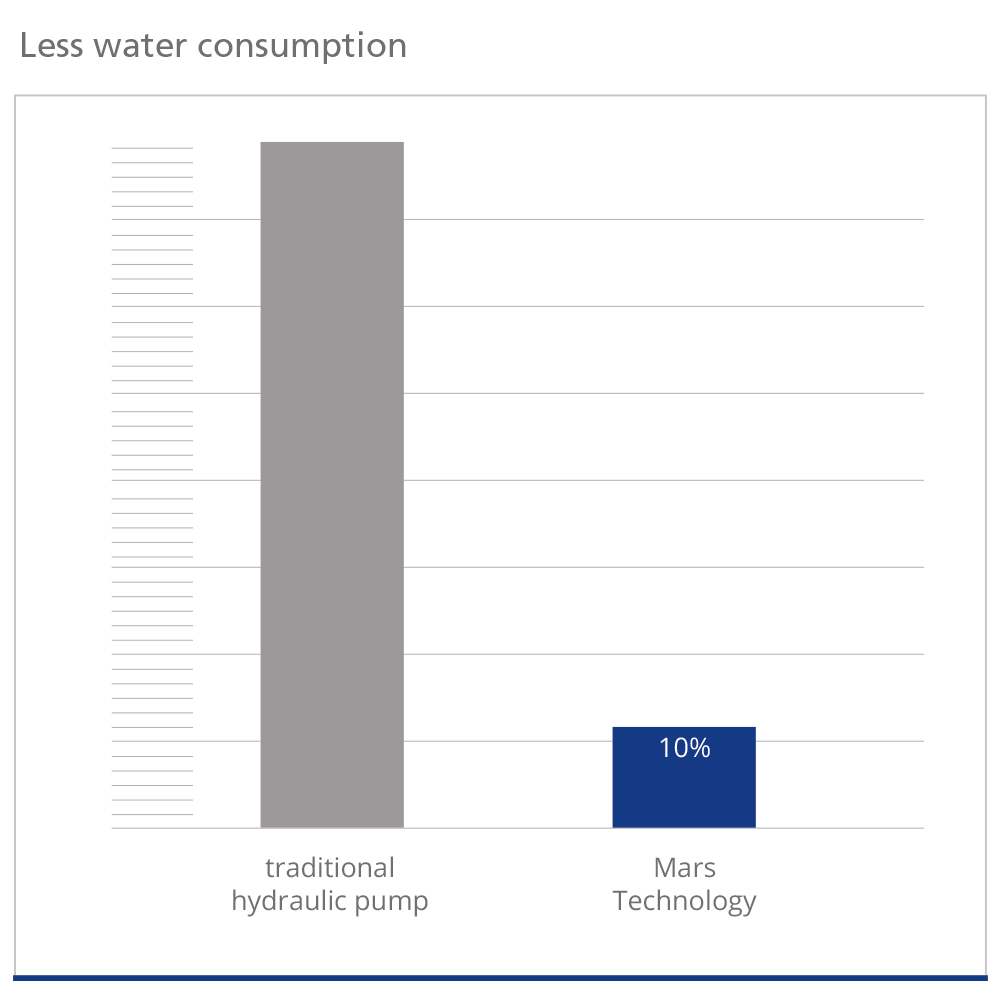

EFFICIENT PERFORMANCE

Ressource-Saving System

DISCOVER MARS

A SUCCESS STORY

The Mars has been on the market for over 10 years and continues to be the top of the line in hydraulic injection-molding technology – the world’s best-selling injection-molding machine.